Infrared inspections for Buildings.

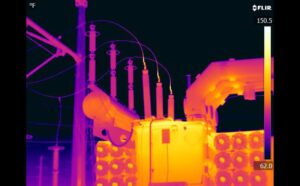

Do you need infrared inspections for buildings or Infrared inspections for electrical to find hot spots caused by defects in connections and components? Infrared electrical inspection or thermography is used to find areas of excess heat (caused by increased resistance) so that problems can be corrected before a component fails, causing damage to the component, creating safety hazards and productivity loss. Because increased heating is a sign of failure, an infrared electrical inspection is the best diagnostic tool for finding these hot connections in the early stages of degeneration. This is why your insurance company may have asked for an electrical infrared inspection to find and prevent problems before they cause damage to your personnel, equipment, and, inspection facility, thus reducing downtime and fewer repair costs to the owners, etc.

Electrical infrared inspections

|

|

Need Infrared Inspections for Buildings & Electricalshould be an integral part of any electrical preventive maintenance (EPM) program. This type of need infrared inspections can help save money by verifying equipment is operating at peak efficiency and reducing costly downtime in the event of electrical system failure. It also can help save the costs associated with the damage that a fire may cause if an electrical system overheats or fails catastrophically. This inexpensive inspection program has evolved into a valuable preventive maintenance tool. The following information discusses the benefits of infrared inspection and explains how the inspections are conducted. The heating effect continued to increase past the red in an infrared region (“below red”). He measured radiation effects from fires, candles, and stoves and deduced the similarity of light and heat. Today, devices can be designed to detect, amplify and display radiation from the visible or infrared portions of the spectrum. Using infrared for electrical infrared inspection and using infrared technology as part of an electrical infrared inspection program works on the principle that electrical equipment typically gives off heat. In contrast, malfunctioning overloaded electrical equipment will give off excessive heat due to increased electrical resistance. This heat can be detected with the use of infrared inspections. Using an infrared camera or video recorder, the heat can be converted to an image that can be seen and recorded for analysis. What Infrared Inspections Actually doThe infrared camera can display various temperatures that are being recorded and the temperature differential between “normal” and malfunctioning equipment. The need infrared inspections for buildings or electrical equipment images can identify precisely what equipment is affected and how heavy equipment runs problem exists based on temperatures and temperature differentials. The images can be inserted into a report to help explain the problem and any suggested repairs or improvements. Infrared should be scheduled before doing any repairs to electrical equipment. This will allow flexibility in resolving problems found during the inspection. Infrared inspections are non-destructive methods during normal business operations at or near capacity. Equipment should run for at least one hour before an inspection. There is no need for downtime or a special tear-down of the equipment to perform the electrical infrared inspection. However, equipment covers must be removed to ensure effective scanning. Because busway conductors are so close to enclosures, the covers may not need to be removed during infrared inspections for electrical equipment. Thermography uses specially designed infrared video or still cameras to make images (called thermograms) that show surface heat variations. This technology has a number of applications. Infrared inspections for buildings and electrical systems can detect abnormally hot electrical connections or components. Thermograms of mechanical systems can detect the heat created by excessive friction. Energy assessors use thermography as a tool to help detect heat losses and air leakage in building envelopes. Infrared scanning allows energy assessors to check the effectiveness of insulation in a building’s construction. The resulting thermograms help assessors determine whether a building needs insulation and where in the building it should go. Because wet insulation conducts heat faster than dry insulation, thermographic scans of roofs can often detect roof leaks. In addition to using thermography during an energy assessment, you should have a scan done before purchasing a house; even new houses can have defects in their thermal envelopes. You may wish to include a clause in the contract requiring a thermographic scan of the house. A thermographic scan performed by a certified technician is usually accurate enough to use as documentation in court proceedings. EMA Structural Engineers Daytona Beach FL, 32114 – Manta.com |